Products

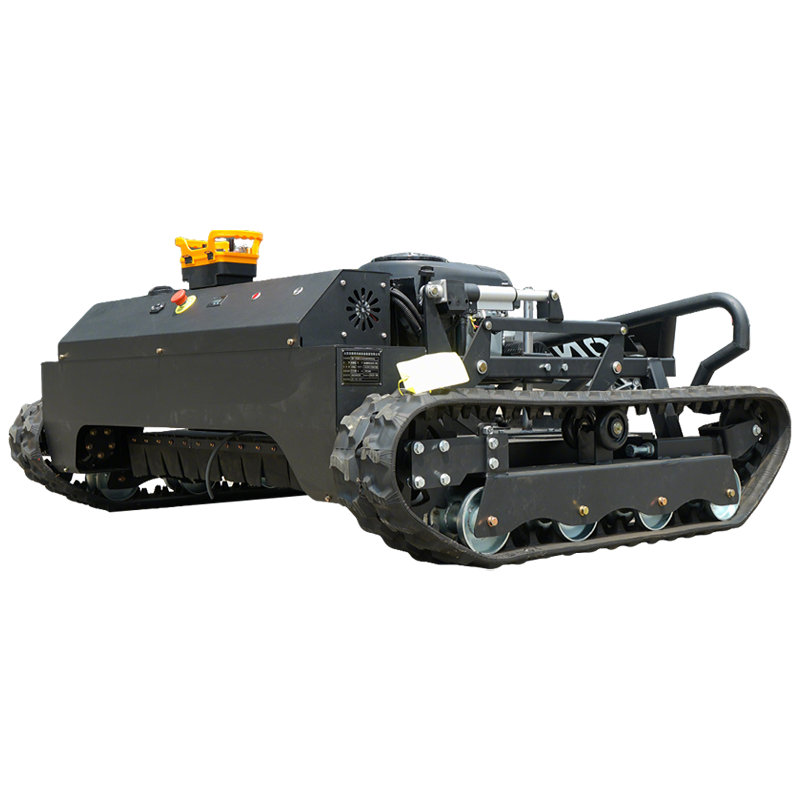

GC-M80TC crawler conveyor belt slag raking machine is specially designed for efficient slag discharge operation in underground construction. 7.8T weight with 5000mm×1650mm×1750mm compact shape. The weight of the machine is 7.8T with the compact shape of 5000mm×1650mm×1750mm, and it can run stably in the limited space. 22kw motor power drive, the loading capacity reaches ≈60m³/h, combined with crawler walking and flexible excavation and conveying system, whether it is mine tunnel, tunnel construction, or underground pipeline corridor construction, it can complete the tasks of slag removing, loading and transferring in a fast and efficient way. The combination of crawler traveling and flexible excavating and conveying system can quickly and efficiently complete the slag picking, loading and transferring tasks, and greatly improve the progress of the project, whether it is mine tunneling, tunnel construction or underground pipe corridor construction.

Usage Scenarios

Mining operation: In the mining tunnel, GC_M80TC can easily cope with the inclined and rugged tunnel ground with its ≤20° climbing ability and track design; its 4.5km/h high-speed traveling mode can quickly go back and forth between the working surface and the slag outlet; its ±45° maximum slewing angle and ≥4200mm digging width can efficiently clean up the slag after blasting and ensure the mining operation continues to move forward.

Tunnel construction: in the narrow space of the tunnel, its width of 1650mm and height of 1750mm, can be freely shuttled, the minimum turning radius of 3600mm to ensure that the flexible turning in the curves; 1800mm - 2700mm digging height and ≥ 1600mm digging distance, accurate picking of slag in the tunnel, through the conveyor belt for rapid transit, to protect the tunnel digging.

Underground pipeline corridor construction: In the face of complex operating environment during the construction of underground pipeline corridors, GC_M80TC's 200mm ground clearance effectively avoids chassis cuts; 1300mm - 1600mm (can be increased) unloading height and 1700mm (can be extended) unloading distance, adapted to the loading needs of different transportation vehicles, and efficiently completes the earth removal, helping the smooth progress of pipeline corridor construction.

Main parameters

Model | GC-M60TC | GC-M80TC |

Weight | 7.8T | 7.8T |

Overall dimension(LxWxH) | 5000mm×1650mm×1750mm | 5000mm×1650mm×1750mm |

Loading Capacity | ≈60m³/h | ≈60m³/h |

Min turning radius | 3600mm | 3600mm |

Climbing ability | ≤20°Hard ground | ≤20°(Hard ground) |

Traveling Speed | High:4.5km/h low:2km/h | High:4.5km/h low:2km/h |

Ground clearance | 200mm | 200mm |

Nominal working pressure | 20mpa | 20mpa |

Motor Power | 22kw | 22kw |

Max.materials by size(LxWxH) | 680mm×600mm×500mm | 680mm×600mm×500mm |

Applicable section(WxH) | ≥2.0m×2.0m | ≥2.0m×2.0m |

Excavating Width | ≥4200mm | ≥4200mm |

Excavating Distance | ≥1600mm | ≥1600mm |

Excavating Height | 1800mm-2700mm | 1800mm-2700mm |

Excavating Depth | ≥450mm | ≥450mm |

Uninstall Height | 1300mm-1600mmCan be heightened | 1300mm-1600mm(Can be heightened) |

Minimum Loading Height | 1200mmVariable | 1200mm(Variable) |

Uninstall Distance | 1700mmCan be lengthened | 1700mm(Can be lengthened) |

| Max.rotation angle | ±45° | ±45° |

Why GC-M80TC

High-efficiency operation, improve the progress: ≈60m³/h high loading capacity, with flexible excavation and conveying system, quickly clean up the slag, reduce the time of engineering slag discharge, accelerate the overall construction progress.

Flexible control, adapting to complexity: ±45° maximum slewing angle, adjustable digging height and distance, as well as heightened and lengthened unloading parameters, so that the equipment can work accurately in complex working conditions; two-speed walking and ≤20° climbing capacity, to cope with different terrains with ease.

Compact and stable, unobstructed access: 7.8T machine weight with compact shape, stable and reliable operation; 1650mm width and 200mm ground clearance, can freely shuttle in narrow and low working space, easily pass through all kinds of construction channels.

Reliable and durable performance: 22kw motor power and 20mpa rated working pressure provide stable power; high-quality track and hydraulic system design ensures the equipment to run stably for a long period of time under high-intensity operation and reduces maintenance cost.

Contact us today for customized configurations and real-time quotes.